Rubber Gaskets

A.J. Rubber & Sponge Ltd. fabricates the bulk of its custom gaskets from rubber materials including:

- Neoprene rubber

- EPDM (ethylene propylene diene monomer) rubber

- Silicone rubber

- SBR (styrene butadiene rubber)

- Nitrile / buna-n rubber

- CI (cloth inserted) rubber

- Military specification rubber

- EP (ethylene propylene) rubber

- Butyl rubber

- Natural rubber

- Fluorocarbon rubber

- And more

Each custom gasket material possesses a myriad of different characteristics and parameters that can include temperature ranges, subjection to harsh chemicals such as hydrocarbons, abrasion, ultraviolet (UV) light exposure, compression set, flange load, tensile strength and rubber aging. More often than not, the industry uses fillers and additives to achieve the aforementioned properties in the rubber custom gasket of your choice. Available in both natural and synthetic form, rubber has been the material of choice for the manufacturers of custom gasket materials due to its unrivaled ability to reform to its original shape and state even after the application of an exterior compressing, depressing or deforming force (this characteristic is also directly related to the tensile strength of various kinds of rubber). Rubber is better suited for low temperature applications than high temperature ones, so that both the shape and functionality of the rubber custom gasket are well preserved.

At A.J. Rubber & Sponge Ltd., we help guide customers through the many choices of rubber material available to them in an attempt to ensure that they have the best rubber material for their rubber custom gasket application. We stock and are capable of sourcing many kinds of rubber materials, ensuring fast turnaround times for the production of your rubber custom gaskets.

SBR (styrene butadiene rubber) custom gaskets:

SBR (styrene butadiene rubber), also known as GRS, buna-s and buna s, is a material that A.J. Rubber & Sponge Ltd. commonly manufactures custom gaskets with, and our experience with this versatile material has taught us quite a bit about it:

- The typical elongation percentage of SBR (styrene butadiene rubber) is approximately 500%.

- SBR (styrene butadiene rubber) custom gasket material has a recommended temperature operating range of -40°C to 100°C (-40°F to +212 °F).

- It is not resistant to ozone, sunlight, rain, sleet, snow or other weather elements, and they are not recommended for use in any type of electrical application

- SBR (styrene butadiene rubber) usually transitions into a glass-like substance at a temperature of approximately -55°C (131°F) (also referred to as the “glass transition temperature”).

- SBR (styrene butadiene rubber) custom gaskets are very commonly incorporated into pneumatic tires, tubes, footwear heels and soles, as well as for many custom gasket manufacturing applications. To learn more about A.J. Rubber & Sponge Ltds. SBR (styrene butadiene rubber) custom gaskets, please contact us today.

Nitrile rubber custom gaskets:

Although some of the custom rubber gaskets A.J. Rubber & Sponge Ltd. manufactures are composed of a natural rubber, NBR (acrylonitrile butadiene rubber), which is also referred to as buna-n rubber, belongs to a family of synthetic rubber custom gasket materials that are comprised of a copolymer of acrylonitrile and butadiene. NBR (acrylonitrile butadiene rubber) custom gaskets physical and chemical properties can vary a lot depending on the composition of the specific acrylonitrile species involved. The higher the concentration of acrylonitrile in the polymer, the higher the final rubber gaskets resistance to oils will be; however, this compromises the flexibility of the custom rubber gasket, making it more rigid.

NBR (acrylonitrile butadiene rubber) custom gaskets are highly resistant to:

- Oil

- Gasoline

- Diesel

- Grease

- Other types of chemicals

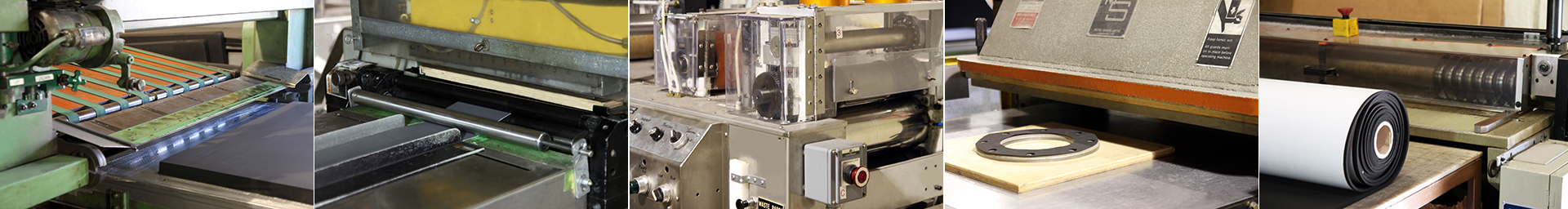

This characteristic makes NBR (acrylonitrile butadiene rubber) custom gaskets an ideal choice for use in applications where components are exposed to corrosive chemicals on a regular basis. A.J. Rubber & Sponge Ltd. does not custom fabricate nitrile rubber o-rings or nitrile rubber molding components, nor do we use the trade names Eroprene, Nipol or Krynac. Our production facility, however, is completely capable of custom manufacturing NBR (acrylonitrile butadiene rubber) custom gaskets of all shapes and sizes using our die cutting presses and other related machinery.

A.J. Rubber & Sponge Ltd. has a more than 45 year history of fabricating custom die cut and custom kiss cut custom rubber gaskets, and more specifically, we fabricated NBR (acrylonitrile butadiene rubber) custom gaskets for use across a wide variety of applications and industries. To learn more about our NBR (acrylonitrile butadiene rubber) custom gasket capabilities, please give us a call today.

CI (cloth inserted) rubber custom gaskets:

At A.J. Rubber & Sponge Ltd., our CI (cloth inserted) rubber custom gasket inventory includes neoprene rubber gaskets, SBR red rubber gaskets and Nitrile (buna-n) rubber gaskets. CI (cloth inserted) rubber custom gaskets are composed from a rubber sheet material that is reinforced with one or more plies of cloth, usually polyester, nylon, cotton and/or fiberglass fabric, for added strength that gives the CI (cloth inserted) rubber custom gaskets additional stability when used in flanged custom gasket applications requiring mechanical fastening, or where mechanical tension due to compression loads is high.

CI (cloth inserted) rubber custom gaskets are best suited for applications where hot or cold water and gases are being transferred, such as:

- Water meters

- Control devices

- Batching devices

- Regulators

- Booster pumps

- Diaphragms

CI (cloth inserted) neoprene rubber custom gaskets are suitable in applications that require minimal oil resistance due to their inability to perform well in such conditions. On the other hand, CI (cloth inserted) SBR red rubber gaskets are much more suitable for use in applications concerning hydraulics and where air, water or low-pressure steam will be passed through the system. For more information on A.J. Rubber & Sponge Ltds. CI (cloth inserted) rubber custom gaskets (neoprene rubber, SBR red rubber or nitrile (buna-n) rubber), please don’t hesitate to contact us.

Military specification rubber custom gaskets:

A.J. Rubber & Sponge Ltd. is a proud defense contractor of a variety of rubber custom gaskets for use in sealing devices that meet the various military rubber requirements and specifications set forth by the Canadian and U.S. military Department of Defense, and other counterparts worldwide. The military specifications for rubber custom gaskets are designed to ensure that elastomeric materials support the mission by meeting standard performance requirements. We take pride in supporting the defense of North America by supplying neoprene rubber custom gaskets, sponge custom gaskets and any sort of military specification rubber custom gaskets that may be required.

Tier 1 and tier 2 military specification rubber custom gasket suppliers are usually somewhat familiar with these standards, but may not fully understand how the details of a particular gasket specification can affect purchasing and manufacturing decisions from the standpoint of the military. This is where A.J. Rubber & Sponge Ltd. has an advantage. As our technology advances, so does the design and manufacturing methods of producing military specification rubber custom gasket products, ensuring that our rubber custom gaskets used for military applications have the ability to withstand aggressive environments overseas. Rubber custom gasket performance is very much affected by drastic fluctuations in temperature, and this is something that needs to be considered at the time of choosing appropriate gasketing materials. A.J. Rubber & Sponge Ltd.’s military specification custom gasket materials are capable of being used in environments with continuous service temperatures as low as -51ºC to as high as 200ºC (-60ºF to as high as 401ºF).

To further explore the military specification rubber custom gaskets that A.J. Rubber & Sponge Ltd. produces, please give us a call today.

Silicone rubber custom gaskets:

As far as custom gaskets are concerned, silicone rubber custom gaskets are used in a wide range of industries for a few important reasons:

- Silicone rubber is designed to be operational between extreme temperatures of -55°C and +300°C (-67°F and 572°F).

- Superior to conventional rubbers in terms of tensile strength, elongation, tear strength and compression set.

- Will not react with most chemicals in any given environment due to silicone rubbers inert property.

- Highly resistant to environment environmental factors such as ozone exposure, ultraviolet (UV) radiation, heat or any other factor contributing to the custom gaskets aging process.

- Excellent insulator of electricity

The above mentioned properties of silicone rubber custom gaskets makes them ideal for use in:

- Molding applications in the medical industry

- Production of implants

- Electrical connector insert applications in electronics manufacturing

- As silicone gum in the compression molding process

- Any high altitude / high temperature sterilization environment in the aerospace or medical industries

Silicone rubber custom gaskets contain a "backbone" of silicon-oxygen links as opposed to the carbon to carbon (C to C) backbone found in traditional, organic rubber, making it a very versatile custom gasket for use in many different applications. Please contact A.J. Rubber & Sponge Ltd. to learn more about the silicone rubber custom gaskets that we manufacture.

Neoprene rubber custom gaskets:

Neoprene rubber custom gaskets are composed of a synthetic rubber known as neoprene rubber which is very versatile and used in a vast range of applications ranging from construction to medical. A.J. Rubber & Sponge Ltds. neoprene rubber custom gaskets resist degradation from:

- Sunlight

- Ozone

- Poor weather conditions.

Neoprene rubber custom gasketes also perform well when in contact with oils and chemicals, due to their synthetic nature. Neoprene rubber custom gaskets always maintain their form as well as their tensile strength over very wide temperature ranges, much like silicone rubber gaskets and EPDM (Ethylene Propylene Diene Monomer) rubber gaskets. The versatility of neoprene rubbers gaskets are best showcased in their applications in various industries.

If you would like to learn more about the neoprene rubber custom gaskets that A.J. Rubber & Sponge Ltd. produces, then please feel free to give us a call.

EPDM (ethylene propylene diene monomer) rubber custom gaskets:

Best known for its superior resistance to harsh and toxic chemicals, A.J. Rubber & Sponge Ltd. has the expertise as well as the capability to die cut EPDM (ethylene propylene diene monomer) rubber custom gaskets to your exact specifications in any industry. Although EPDM (ethylene propylene diene monomer) rubber custom gaskets have great chemical resistance, they are most ideal for sealing environments that are not exposed to any sort of:

- Oils

- Gasoline

- Kerosene

- Aromatics

- Aliphatic hydrocarbons

- Halogenated solvents

- Concentrated acids

EPDM (ethylene propylene diene monomer) rubber can typically withstand temperatures ranging from -50°C to 150°C (-58°F to 302°F). For this reason EPDM (ethylene propylene diene monomer) rubber is very often incorporated in the process of fabricating weather custom gaskets, and function as a source of noise reduction / acoustic insulation in the automotive industry. EPDM (ethylene propylene diene monomer) rubber custom gaskets are an excellent source of producing gasket sealing against atmospheric conditions including:

- Sunlight

- Ozone

- Ultraviolet (UV) light exposure

- Wind

- Rain

Should you require additional information on the EPDM (ethylene propylene diene monomer) rubber custom gaskets that A.J. Rubber & Sponge Ltd. manufactures, please contact us today.