Sponge Gaskets

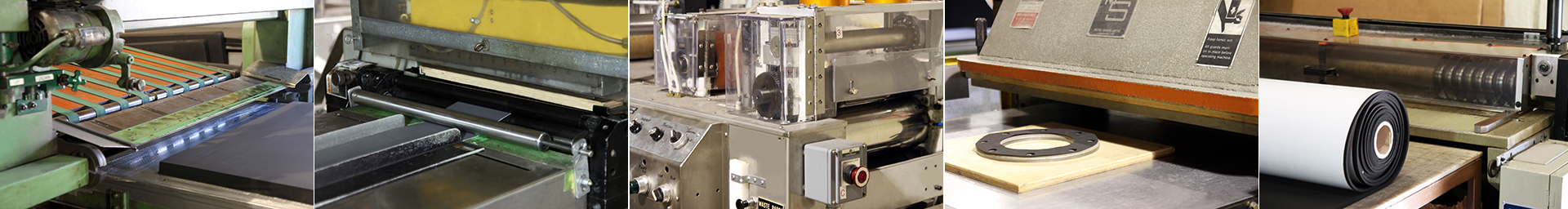

A.J. Rubber & Sponge Ltd. has more than 45 years of experience specializing in the production of precision die cut sponge custom gaskets. We fabricate both open cell sponge custom gaskets and closed cell sponge custom gaskets which are used in various applications over multiple industries. Most grades of the sponge material that A.J. Rubber & Sponge Ltd. uses in the production of our sponge custom gaskets are available in soft, medium and hard densities. Each specific type of sponge that we carry offers a unique set of physical characteristics that are different for each sponge type:

Closed cell silicone sponge custom gaskets

Also commonly referred to as expanded silicone, this type of sponge custom gasket is typically available in thicknesses between 1/16" to 2". The term “closed cell” means that the sponges cells are not interconnected and are therefore impermeable to moisture absorption. A.J. Rubber & Sponge Ltds. closed cell silicone sponge custom gaskets provide superior water sealing under numerous applications. Closed cell silicone sponge custom gaskets have many other unique properties:

- They are very soft as compared to solid silicone gaskets.

- They are comprised of a closed cell structure, making silicone sponge the preferred choice for custom gaskets.

- Their densities are typically defined by the compression force of deflection in a PSI range compressed by 25%. A range of 2 to 5 PSI compression force of deflection is rated as soft, whereas a range of 14 to 20 PSI is rated as hard.

- They derive from an uncured silicone gum source, which then expands to the desired size through a specialized manufacturing process.

For additional information on A.J. Rubber & Sponge Ltds. closed cell silicone sponge custom gaskets, please contact us today.

Closed cell neoprene sponge custom gaskets

A.J. Rubber & Sponge Ltds. closed cell neoprene sponge custom gaskets are commonly used as seals in various devices that are constantly exposed to extreme chemicals, weather elements and other volatile forces such as oil, gasoline, acid, ultraviolet (UV) light radiation, rain, snow, hail, sleet, direct sunlight and ozone exposure. They are often utilized in the automotive manufacturing, oil and gas industries, though they are also frequently applied to the production of various apparatus in the areas of medical equipment fabrication, aerospace and military equipment production, clothing manufacturing, electronics manufacturing, and the assembly of large engines for airplanes, trucks, cars, buses, trailers and various types of watercraft.

A.J. Rubber & Sponge Ltd. die cuts, kiss die cuts and applies PSA (pressure sensitive adhesive) to our closed cell neoprene sponge custom gaskets. Neoprene falls within a family of synthetic rubbers and has many beneficial characteristics, such as:

- Temperature operating ranges of -56.7°C to 93.3°C (-70° F to + 200° F).

- Well suited for long term outdoor applications such as electrical enclosures or weather stripping.

- Ozone resistance as well as resistance to many other weather elements (ultraviolet light, sunlight, etc.).

- Resists the effects of both natural and synthetic oils as well as other chemicals (acids, gasoline etc.)

- Useful over a very wide range of temperatures.

- Resistance to tears or damage caused by flexing and/or twisting.

- Resistance to burning (much better than rubbers that are composed of exclusively hydrocarbon chains).

- Superior resistance to heat (ideal for applications with extremely high temperatures over long periods of time).

A.J. Rubber & Sponge Ltd. have supplied a number of industries with our closed cell neoprene sponge custom gaskets to help them overcome problems requiring sealing under high temperatures and enormous pressures for lengthy periods of time. Closed cell neoprene sponge custom gaskets are designed stay in one place and provide long-lasting permanent sealing for any given application. For technical data on A.J. Rubber & Sponge Ltds. closed cell neoprene sponge custom gaskets, please click on the following links:

AJ-42 spec sheetAJ-43 spec sheetAJ121 spec sheetClosed cell EPDM (ethylene propylene diene monomer rubber) sponge custom gaskets:

Closed cell EPDM (ethylene propylene diene monomer rubber) sponge custom gaskets offer excellent resistance to ozone and oxidation. They also provide superior aging properties and compressibility. This material is used in a variety of outdoor applications such as weatherproofing or electrical enclosures. Temperatures range from -51.1°C to 98.9°C (–60° F to 210° F). For technical data on A.J. Rubber & Sponge Ltds. closed cell EPDM (ethylene propylene diene monomer rubber) sponge custom gaskets, please click on the following links:

EPDM-41 spec sheetEPDM-43 spec sheetClosed cell vinyl nitrile sponge custom gaskets:

Also known as “expanded rubber”, closed cell vinyl nitrile sponge has cells that resemble balloons, whose function is to seal in gas as well as prevent moisture from escaping through the sponge so long as the walls of its cells remain intact. Closed cell vinyl nitrile sponge custom gaskets are very versatile, boasting an application temperature range of -40°C to 82°C (-40°F to 180°F). Closed cell vinyl nitrile sponge custom gaskets tend to have a slightly lower density profile than most other closed cell sponge products, with the added feature of slightly higher water absorption properties than closed cell neoprene rubber materials.

To manufacture closed cell vinyl nitrile sponge, its raw compounds are mixed using the same type of equipment used to mix solid rubber compounds, with the only difference being the presence of a chemical blowing agent. Under the correct combination of heat and pressure (provided by the pre-curing or pre-forming process), the chemical blowing agent decomposes and mixes with the rubber compound to generate nitrogen gas. As this reaction occurs, the mixed batch is placed into an oven and allowed to expand into a bun anywhere from 2" to 4" thick. This bun of closed cell sponge rubber is then left to age and then split into sheets ranging from .062" thick and greater.

For technical data on A.J. Rubber & Sponge Ltds. closed cell vinyl nitrile sponge custom gaskets, please click on the following link:

AJ310 spec sheetClosed cell ECH (epichlorohydene) sponge custom gaskets:

Closed cell ECH (epichlorohydene) sponge is a type of closed cell sponge that is commonly used in the manufacturing of custom gaskets in the automotive industry. Due to its ability to handle continuous temperatures of up to 150°C (300°F), exposure to light oil and fuel, and its resistance to various tupes of weather, sunlight, ozone and oxidization, closed cell ECH (epichlorohydene) sponge is often incorporated into custom gaskets specifically for under-the-hood automotive applications.

For technical data on A.J. Rubber & Sponge Ltds. closed cell epichlorohydene sponge custom gaskets, please click on the following link:

aj ECH spec sheetSBR (styrene butadiene rubber) sponge custom gaskets:

SBR (styrene butadiene rubber) is an elastomeric co-polymer that consists of a combination of styrene and butadiene. It possesses excellent resistance to abrasion as well as superior stability over a range of environments. Other beneficial characteristics of SBR (styrene butadiene rubber) include:

- Very resistant to fats, mineral, natural and synthetic oils, aliphatic hydrocarbons, aromatic hydrocarbons and chlorinated hydrocarbons.

- It transitions into glass at a temperature of approximately -55°C (131°F) (known as the “glass transition temperature”).

- Has a recommended temperature range of -40°C to 100°C (-40°F to +212 °F).

- Typically has an elongation percentage of between 450–500%.

Other common names for SBR (styrene butadiene rubber) include GRS and buna-S or buna S. At A.J. Rubber & Sponge Ltd., we manufacture custom gaskets from SBR (styrene butadiene rubber) for a variety of applications such as:

- Pneumatic tires and tubes

- Footwear heels and soles

- Other custom gasket manufacturing applications

Although our SBR (styrene butadiene rubber) sponge custom gaskets are extremely versatile, they are not very weather resistant (sunlight, ozone, rain etc.), and are therefore not recommended for any type of electrical application. For technical data on A.J. Rubber & Sponge Ltds. SBR (styrene butadiene rubber) sponge custom gaskets, please click on the following link:

AJ8511 spec sheet