Custom Seals

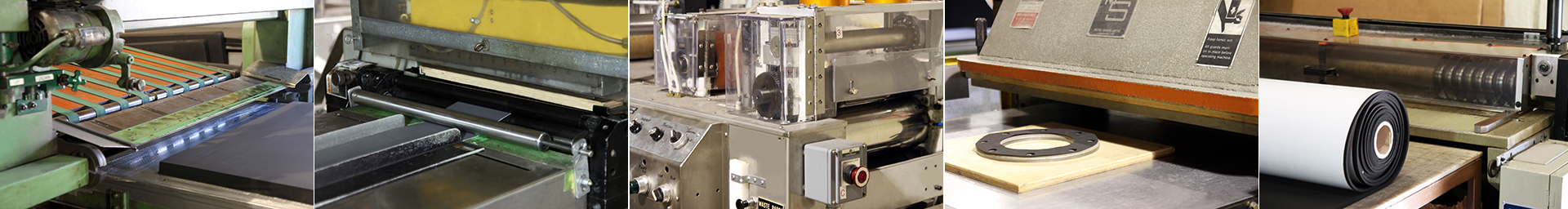

Located in the heart of Hamilton, Ontario, A.J. Rubber & Sponge Ltd. is an industry leader in the area of high quality die cut custom seals manufacturing. As custom seal fabricators we have built and maintained a solid reputation for our reliable, affordable and time conscious products and services; our primary objective is to continue to exceed our customers expectations. Our superior quality custom seals can be die cut, kiss cut or rotary cut, depending on the specific requirements of the production run. A.J. Rubber & Sponge Ltd. maintains fabrication facility equipped with modern, capable machinery, enabling us to consistently meet all of your blueprint specifications and tolerance requirements for custom seal products.

A.J. Rubber & Sponge Ltd. specializes in custom seal fabrication for a variety of industrial applications:

- Appliance & small tool

- Chemical & petro-chemical industry

- Furnace & boiler manufacturers

- Pulp & paper processing plants

- Construction & contracting industry

- Foundry, steel & mining companies

- Steel mills

- Utilities, power generation & tank car manufacturers

- Transportation, electronic, & hi-tech industries

- Pumps & compressors

- Engines: gas, diesel & turbine

- Military, department of defense & ship building industry

- Aerospace & aviation industry

- Oil & gas drilling, production & refining industries

- Machinery, heavy equipment & transformer manufacturers

- Heating, air conditioning, & plumbing industries

- And more!

All of the custom seals we produce for our clients are designed and manufactured to meet their exact outlined specifications. We are capable of supplying precision custom seals that will perform efficiently for their intended purpose. We have the ability to completely customize a seal fabrication production run that meets the specifications of all of your products. A.J. Rubber & Sponge Ltd. relies on customers as well as suppliers for steel rule dies to ensure accuracy. We also keep on hand a number of steel rule dies that you can browse through to select from our array of custom seal fabrication capabilities. We do everything we can to ensure production costs are stable, and that we are capable of meeting extremely tight tolerances. We provide die cut custom seals in quantities ranging from sample prototypes and short runs to large production runs of hundreds of thousands of pieces. A.J. Rubber & Sponge Ltd. takes great pride in our ability to consistently and accurately produce die cut custom seals that function as intended within your application:

- Compressed non-asbestos seals

- Silicone seals

- Polyurethane foam seals

- Rubber seals

- EPDM (ethylene propylene diene monomer rubber) seals

- SBR (red rubber) seals

- Flange seals

- Neoprene seals

- Nitrile (buna-n) seals

- Rubber washers

- Silicone sponge seals

- Closed cell sponge seals

- Cloth-inserted rubber seals

- Foam seals

The non-metallic materials we have available for use in die cut custom seals include:

- Neoprene/EPT (ethylene-propylene-terpolymer)/SBR (styrene butadiene rubber) blended closed cell sponge

- EPDM (ethylene propylene diene monomer rubber) closed cell sponge

- Vinyl nitrile closed cell sponge

- SBR (red rubber) food grade closed cell sponge

- Crosslinked polyethylene

- ECH (epichlorohydren)

- Silicone rubber

- Silicone foam

- Solid rubber ie. neoprene, EPDM (ethylene propylene diene monomer rubber), SBR (red rubber) etc.

- Polyester & polyether open cell foams

- PVC (polyvinyl chloride) foam

- Microcellular urethane

- Sound absorbing foam

In addition to these materials, we are capable of sourcing and producing any type of non-metallic custom seal for any industry. Simply ask us what you are looking for! With over 45 years of industry experience specializing in the manufacturing of precision die cut custom seals and die cut products for a wide range of industries and applications, we offer die cutting services including, but not limited to:

- Steel rule die cutting

- Sheeting

- Rotary die cutting

- Roll slitting

- Kiss cutting

- Punch pressing

- Flatbed horizontal splitting