Foam Gaskets

A.J. Rubber & Sponge Ltd. manufactures a diverse range of foam custom gaskets for commercial and industrial applications. Due to their commonality across a wide selection of industries, there is no shortage of demand for A.J. Rubber & Sponge Ltds. foam custom gaskets.

Silicone foam custom gaskets:

Silicone foam custom gaskets and foam silicone custom gaskets are interchangeable terms used in the custom gasket manufacturing industry (they are essentially the same product). Silicone foam custom gaskets are very similar to silicone sponge custom gaskets, but the way that they are manufactured makes them unique to one another.

Silicone foam custom gaskets range from mostly closed cell to very open cell style structures. Open cell silicone foam custom gaskets are lightweight and produced via a specialized process using liquid silicone ingredients as the base material. In the foam custom gasket manufacturing industry it is well known that low density open cell silicone foam may allow moisture to escape, whereas high density closed cell silicone foam is more suitable for effective water sealing. Either way, with appropriate coverage achieving long term moisture or weather seals with silicone foam is definitely possible thanks to recent advancements in technology in the custom gasket fabricating industry. Closed cell silicone foam custom gaskets work well as environmental seals, and are extremely durable and resistant to environmental fluctuations due to silicones low toxicity features. Open cell silicone foam custom gaskets have a tendency to be best used as shock or vibration gaskets such as those found in automotive applications.

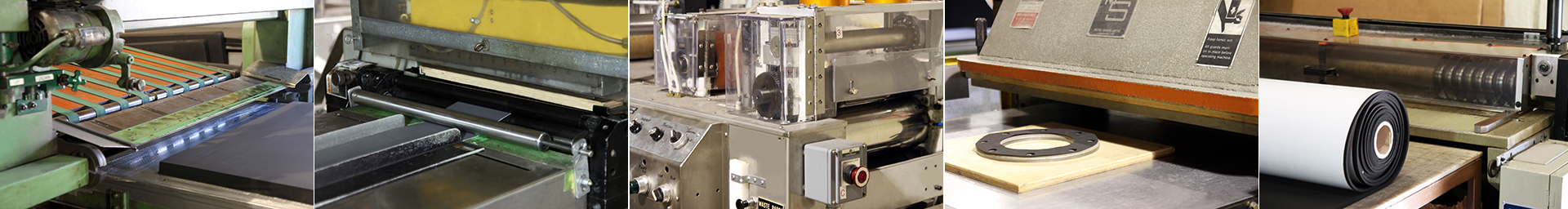

A.J. Rubber & Sponge Ltds silicone foam custom gasket manufacturing process includes:

- Die cutting

- Horizontal splitting

- Roll slitting

- Shearing

- Skiving

- Kiss die cutting

- Custom assemblies

In addition, we are capable of applying a wide variety of PSA (pressure sensitive adhesives) to all silicone foam products. Some of the benefits of silicone foam custom gaskets include:

- Silicone foam custom gaskets have tremendous UV (ultraviolet) light and ozone resistant properties due in part to the inorganic backbone of its molecular structure. This characteristic of silicone foam gaskets is the foundation of their long term performance.

- Silicone foam custom gaskets have a wide temperature operating range of approximately -53°C to 201°C (-65°F to 395°F).

- Silicone foam custom gaskets are not subject to decay by aging or degradation from sunlight.

- Both open cell silicone foam custom gaskets and closed cell silicone foam custom gaskets can be used for keeping out dust which makes them ideal for use in manufacturing plants, industrial buildings, production facilities and other general industrial applications.

- Silicone foam custom gaskets offer excellent compression set resistance (the measure of the materials resilience, or its ability to rebound to its original thickness upon being compressed).

- Closed cell silicone foam custom gaskets possess good water sealing capabilities and relatively low compressive forces, them most ideal for water-related applications.

- Silicone foam custom gaskets have a number of intrinsic flame resistant properties.

A.J. Rubber & Sponge Ltds. popular foam custom gaskets can be used to seal liquids in high-pressure applications, or seal out light, air and dust in low-pressure environments (depending on the make of the raw foam, the material undergoes many different processes to produce low-pressure gaskets by compression of its thickness).

Acoustic foam custom gaskets:

Also referred to as noise reduction gaskets, acoustic foam custom gaskets are commonly grouped as class “O” and are readily converted by A.J. Rubber & Sponge Ltd. in both plain and self adhesive (PSA – pressure sensitive adhesive) backed formats (one or more sides). The thickness of acoustic foam custom gaskets ranges from:

- 1mm up to 100mm thick - without lamination/PSA (pressure sensitive adhesive)

- Greater than 100mm - with lamination/PSA (pressure sensitive adhesive)

Like all foam custom gaskets, acoustic foam custom gaskets are employed for a variety of uses in a vast array of environments, especially those involving noise reduction, thermal insulation and/or vibration control (such as in the automotive assembly industry). For more information on A.J. Rubber & Sponge Ltds. acoustic foam custom gaskets, please contact us today.

Polyurethane foam custom gaskets:

Polyurethane foam is a type of open cell flexible foam material that is commonly incorporated in the manufacturing process of custom gaskets. It is an economical and affordable product, best suited for applications including, but not limited to:

- Cushioning

- Dust sealing

- Moisture sealing

- Thermal & acoustic insulation

A.J. Rubber & Sponge Ltds. polyurethane foam custom gaskets are available with PSA (pressure sensitive adhesive) backing as an option. For technical data on our polyurethane foam custom gaskets, please click on the following link:

AJ702-2 spec sheetMicrocellular urethane foam custom gaskets:

Microcellular urethane foam offers superior compression set resistance and are estremely resilient, producing a gasket seal that absolutely will not break down over extended use. These characteristics of microcellular urethane foam allow this foam custom gasket material to be used in a vast range of industry applications, and will perform well under the temperature range of -40°C -90°C (-40°F to 194°F). For additional information on A.J. Rubber & Sponge Ltds. microcellular urethane foam custom gaskets, please contact us today.

Cross-linked polyethylene foam custom gaskets:

Cross-linked polyethylene foam is another very common foam material used for the production of custom gaskets. Cross-linked polyethylene foam has many ideal properties making it ideal for a large variety of applications:

- Superior thermal insulating

- Excellent chemical resistance

- Smooth surface

- Excellent consistency

- Ideal gauge control

- Resistance to high temperature

- Low water absorption.

For technical data on A.J. Rubber & Sponge Ltds. cross-linked polyethylene foam gaskets, please click on the following link:

AJ199 spec sheet