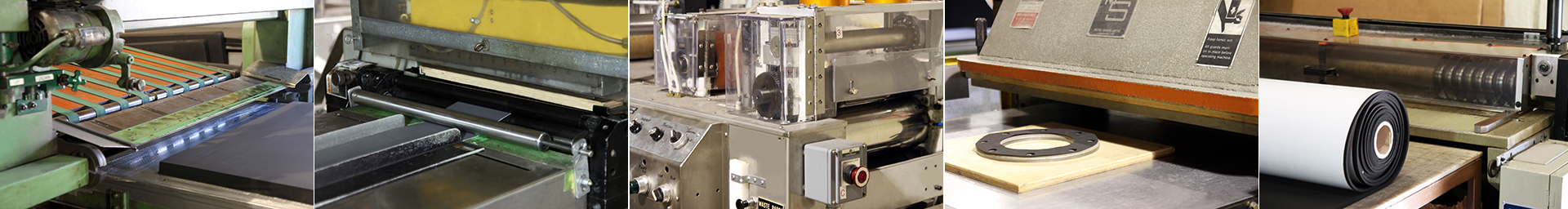

Sheeting & Slitting

A.J. Rubber & Sponge Ltd. takes advantage of several processes including sheeting and slitting for custom gasket and seal fabrication. Slitting is a term used to describe a type of cutting where large rolls or sheets of material are cut using extremely sharp rotary blades on flatbed presses or otherwise. These materials can include:

- Rubber

- Polyethylene foam

- Sponge

- Solid rubber

- PVC (polyvinyl chloride) foam

- Neoprene

- EPDM (ethylene propylene diene monomer rubber)

- Silicone rubber

- Silicone foam

In the process of custom gasket material slitting, straight lines are cut lengthwise into large rolls or sheets of material in order to create strips of rubber, foam or sponge that are narrower in width. As the roll or sheet of rubber, foam, sponge or other non-metallic custom gasket material runs through the circular blades of the roll slitter, the cuts are precisely made. In the industry, and for those that are familiar with the sheeting or slitting process, the circular blades are referred to as knives and can actually be moved to make material strips of differing widths for the custom gasket or seal fabrication process. Slitting blades are designed specifically for each required job. The three critical determinants of the blade configuration include:

- The work piece material thickness

- The type of material to be slit

- The specific tolerances that must be held while slitting

To find out more about our sheeting or slitting services, please contact A.J. Rubber & Sponge Ltd. today.