Neoprene Gaskets

A.J. Rubber & Sponge Ltd. is capable of manufacturing a large range of custom gaskets from rubber materials including neoprene, a synthetic rubber very commonly used in the production of custom gaskets for a large variety of industries, such as:

- Medical equipment manufacturing

- Aerospace industry

- Military equipment manufacturing

- Automotive component fabrication

- And many more

Based on polychloroprene, neoprene was developed as an oil resistant alternative to natural rubber products, since many products such as custom gaskets are exposed to environments where they may come in direct contact with oils. Neoprene custom gaskets possess a vast range of beneficial characteristics, such as:

- Being useful over a very wide range of temperatures.

- Resistance to tears or damage caused by flexing and/or twisting.

- Resistance to burning (much better than rubbers that are composed of exclusively hydrocarbon chains).

- Ozone resistance as well as resistance to many other weather elements (ultraviolet light, sunlight, etc.).

- Resistance to both natural and synthetic oils as well as other chemicals.

As such, neoprene custom gaskets are considered diverse in that they suit many different applications. Neoprene custom gaskets and neoprene grommets are commonly used in devices that are always subject to extreme chemicals, temperatures and other volatile forces. Neoprene custom gaskets are often used in the automotive, and oil and gas industries as seals against toxic environments and extreme weather elements. Neoprene custom gaskets are also frequently used in the assembly and fabrication of large engines for airplanes, cars, buses, trailers, trucks, and various styles of watercraft. On the other hand, neoprene grommets are more applicable to the manufacturing of electrical connectors in the aerospace and electronics industries. Neoprene custom gaskets have also become a popular product in modern applications such as clothing or electronic cases.

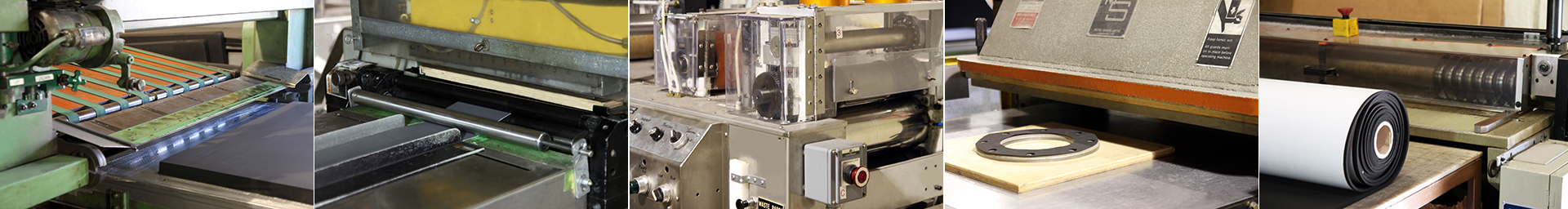

Because they are synthetic, neoprene custom gaskets have a tendency to be extremely resistant to heat, making them ideal for applications where lengthy periods of high temperatures are involved. A.J. Rubber & Sponge Ltd. has supplied many manufacturers with neoprene custom gaskets to assist them in tackling any problems they may have which require sealing under high temperatures and enormous pressures for drawn-out amounts of time. We die cut, kiss die cut and apply PSA (pressure sensitive adhesive) to our neoprene custom gaskets, which are generally meant to provide a permanent seal for any given application, and are designed to remain in one place and provide long-lasting sealing.

To further explore A.J. Rubber & Sponge Ltds. neoprene custom gasket capabilities, give us a call today!