Kiss Cutting

Kiss cutting is a form of die cutting whereby a pressure sensitive adhesive (PSA) backed custom gasket or seal is partially cut through, allowing the custom gasket or seal to retain its pressure sensitive adhesive (PSA) backing as well as its liner, allowing for a “peel and stick” application upon use. One of the benefits of kiss cutting is that it makes custom gasket and seal transportation easier, and it reduces any risk of damage during shipment. Kiss cutting is the perfect solution for customers that require the ability to adhere their seals or gaskets to their final product such as in the automotive industry for vibration control applications.

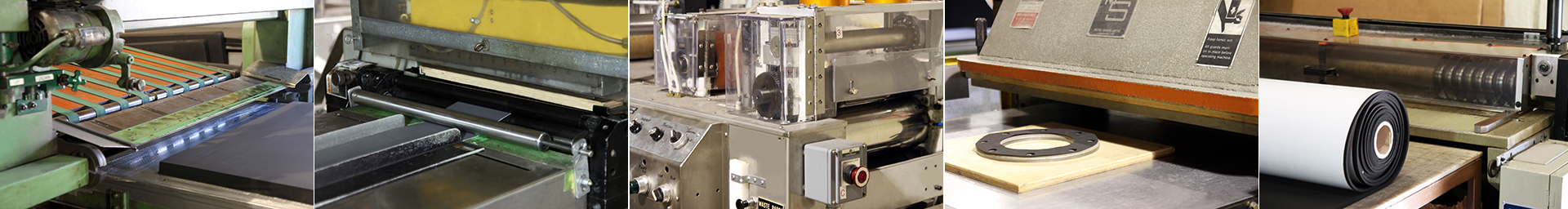

Our modern die cutting presses enable us to ensure precision kiss cut pieces, whether it’s neoprene custom gaskets and seals, sponge custom gaskets and seals, foam custom gaskets and seals or rubber custom gaskets and seals. With the efficient automation of our die cutting presses, there are never any missed-cut or partially-cut pieces. All custom gaskets and seals fabricated during our kiss cutting process simply peel cleanly and evenly from their release liner, which is typically of a paper material. We also never experience any double cut parts and always maintain a consistent gap between each part. Any kiss cutting jobs can be customized in such a way that only the final pieces are attached to the release liner, allowing the scrap material to be easily removed so that only useable custom gaskets and seals remain on the roll for convenience.

A.J. Rubber & Sponge Ltd. is able to kiss cut any number of products, such as:

- Rubber custom gaskets

- Silicone custom gaskets

- Nitrile (buna-n) custom gaskets

- Compressed non-asbestos custom gaskets

- Neoprene custom gaskets

- Sponge custom gaskets

- Rubber custom gaskets

- EPDM (ethylene propylene diene monomer rubber) custom gaskets

- Rubber washers

- Closed cell sponge custom gaskets

- Flange custom gaskets

- Foam custom gaskets

- SBR (red rubber) custom gaskets

- Cloth-inserted rubber custom gaskets

- Polyurethane foam custom gaskets

- Silicone sponge custom gaskets

Kiss-cutting is available for all adhesive backed pieces, or for those non-adhesive materials that come pre-cast on a paper release liner. For the non-adhesive materials that require kiss-cutting but do not come pre-cast, a low tack plastic film is usually incorporated to provide the transport liner. Kiss cutting is best suited for the fabrication of custom gaskets and seals that are going to be used frequently in the final production process of your product. The kiss cut custom gaskets and seals can be rolled up on a self-adhesive paper or plastic liner for convenient dispensing or storage.

A.J. Rubber & Sponge Ltd. can provide a full range of products using kiss cutting) from aerospace custom gaskets and seals to rubber custom gaskets and seals for the automotive industry. Our precision die cutting equipment in conjunction with our machining experience over the last 45 years is more than sufficient to produce custom gaskets and seals on sheets or rolls of self-adhesive lining material. In order to guarantee the success of your kiss cutting project, we will assist you in making the best custom gasket or seal material choice for your specific application.